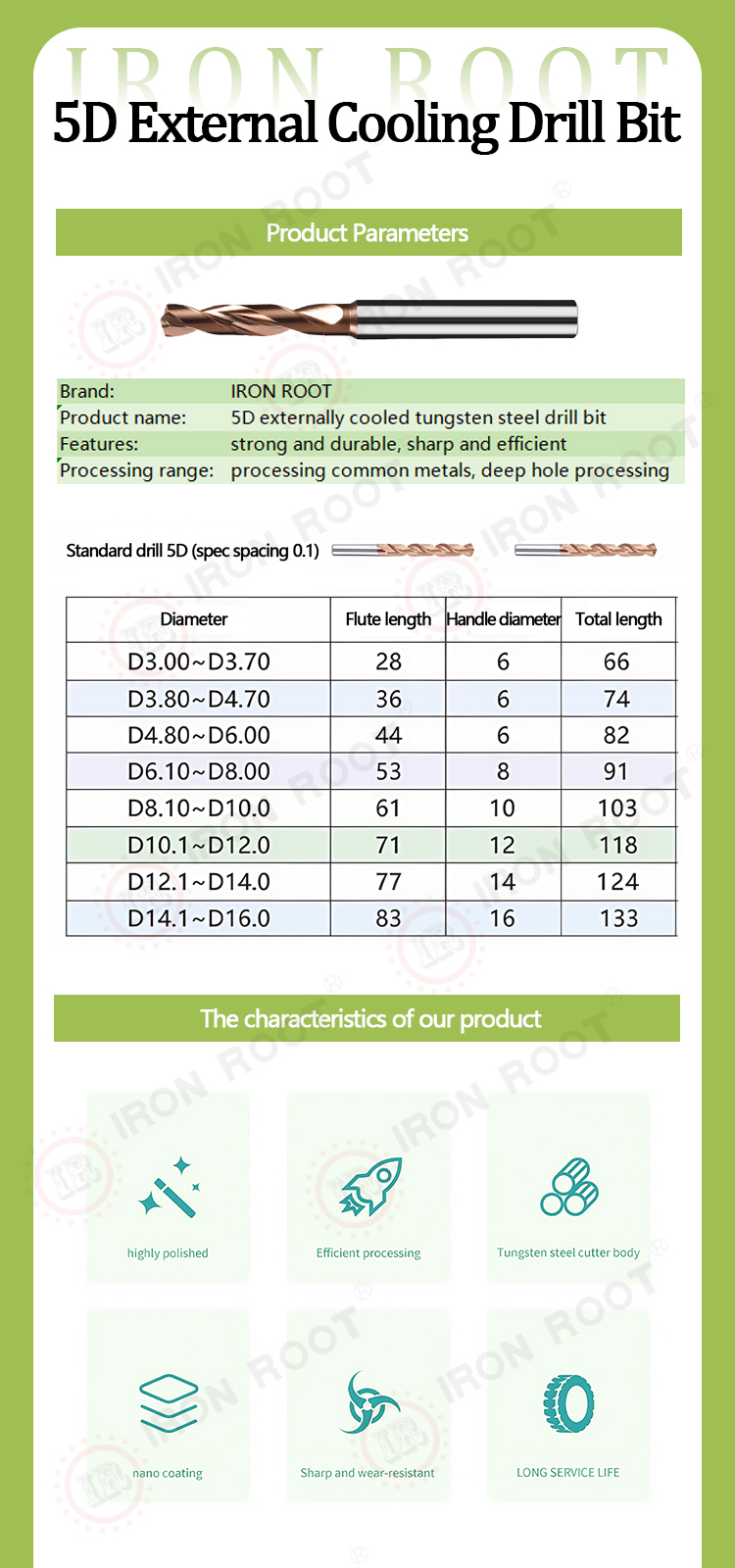

5D External Cold Tungsten Steel Drill Bit 5 Times The Diameter Of Deep Hole Processing Carbide Coating

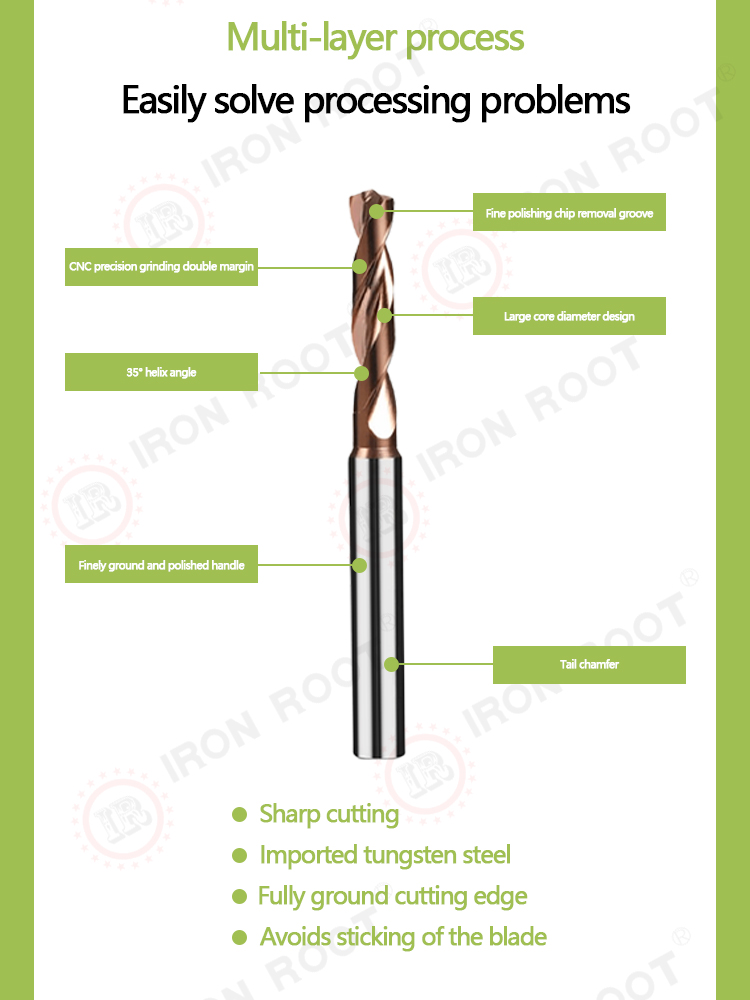

Material and process advantages

Tungsten steel or carbide material is used, which has high hardness (up to HRA90 or above) and wear resistance, and is suitable for processing high-hardness materials such as stainless steel and alloy steel.

Surface coating technology (such as REVOD coating and Swiss coating) improves high temperature resistance and extends tool life by more than 30%. Cooling is achieved through external coolant injection, which is compatible with ordinary machine tools without internal cooling channels and reduces the threshold for equipment use.

Compared with the internal cooling structure, the external cooling drill has higher overall strength and is suitable for large feed processing scenarios115.

Performance and efficiency advantages

The 5D specification supports deep hole processing (hole depth up to 5 times the diameter), meeting the precision processing requirements of aerospace, automotive parts, etc.

The fixed handle anti-vibration design reduces vibration and improves processing accuracy and surface finish8.

Adapted to high-speed cutting of CNC machine tools (speed can reach more than 8000rpm), the feed rate is increased by 20%-30% compared with traditional drills.

The center water outlet or spiral groove design optimizes chip evacuation efficiency and reduces the risk of built-up edge.

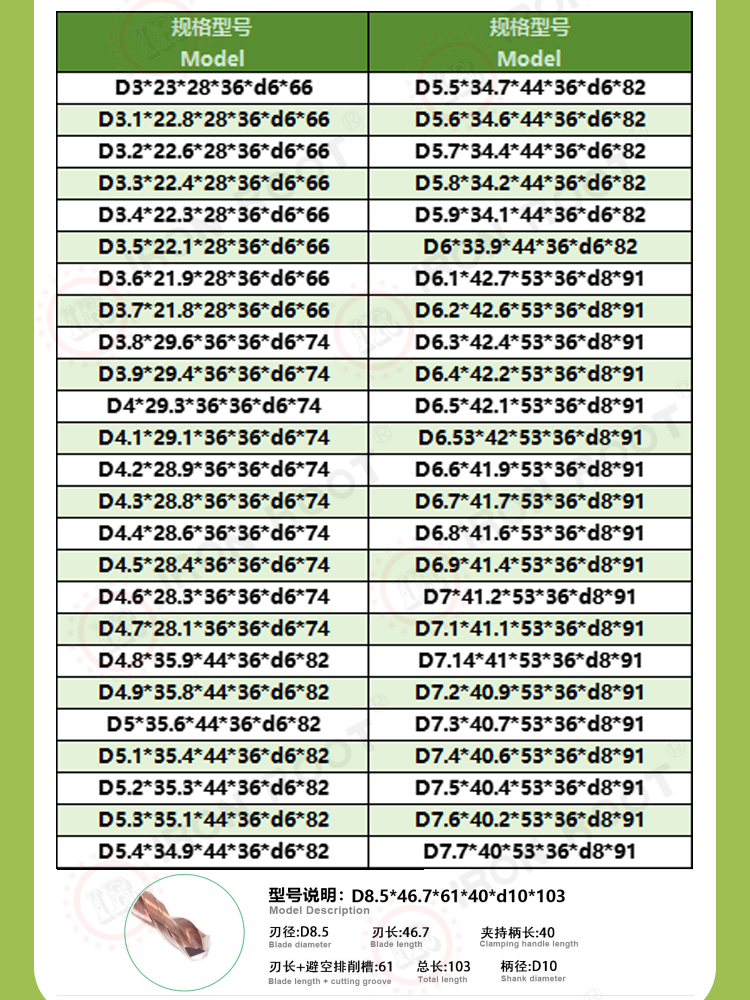

| 规格型号 Model | 规格型号 Model | ||

| D3*23*28*36*d6*66 | D5.5*34.7*44*36*d6*82 | ||

| D3.1*22.8*28*36*d6*66 | D5.6*34.6*44*36*d6*82 | ||

| D3.2*22.6*28*36*d6*66 | D5.7*34.4*44*36*d6*82 | ||

| D3.3*22.4*28*36*d6*66 | D5.8*34.2*44*36*d6*82 | ||

| D3.4*22.3*28*36*d6*66 | D5.9*34.1*44*36*d6*82 | ||

| D3.5*22.1*28*36*d6*66 | D6*33.9*44*36*d6*82 | ||

| D3.6*21.9*28*36*d6*66 | D6.1*42.7*53*36*d8*91 | ||

| D3.7*21.8*28*36*d6*66 | D6.2*42.6*53*36*d8*91 | ||

| D3.8*29.6*36*36*d6*74 | D6.3*42.4*53*36*d8*91 | ||

| D3.9*29.4*36*36*d6*74 | D6.4*42.2*53*36*d8*91 | ||

| D4*29.3*36*36*d6*74 | D6.5*42.1*53*36*d8*91 | ||

| D4.1*29.1*36*36*d6*74 | D6.53*42*53*36*d8*91 | ||

| D4.2*28.9*36*36*d6*74 | D6.6*41.9*53*36*d8*91 | ||

| D4.3*28.8*36*36*d6*74 | D6.7*41.7*53*36*d8*91 | ||

| D4.4*28.6*36*36*d6*74 | D6.8*41.6*53*36*d8*91 | ||

| D4.5*28.4*36*36*d6*74 | D6.9*41.4*53*36*d8*91 | ||

| D4.6*28.3*36*36*d6*74 | D7*41.2*53*36*d8*91 | ||

| D4.7*28.1*36*36*d6*74 | D7.1*41.1*53*36*d8*91 | ||

| D4.8*35.9*44*36*d6*82 | D7.14*41*53*36*d8*91 | ||

| D4.9*35.8*44*36*d6*82 | D7.2*40.9*53*36*d8*91 | ||

| D5*35.6*44*36*d6*82 | D7.3*40.7*53*36*d8*91 | ||

| D5.1*35.4*44*36*d6*82 | D7.4*40.6*53*36*d8*91 | ||

| D5.2*35.3*44*36*d6*82 | D7.5*40.4*53*36*d8*91 | ||

| D5.3*35.1*44*36*d6*82 | D7.6*40.2*53*36*d8*91 | ||

| D5.4*34.9*44*36*d6*82 | D7.7*40*53*36*d8*91 |

- anterior : 58 ° Cárburo Twist de vástago fijo Tiratorio de perforación de calificación industrial Herramienta de perforación

- próximo : Broca de taladro de refrigerante interna 3D para metalurgia - herramienta CNC de alta precisión de carburo de tungsteno para acero inoxidable, aleación de titanio y perforación de agujeros profundos